This value stream mapping tutorial aims to help you familiarize yourself with the concept of value stream mapping. It offers a detailed overview on everything related to VSM, from its origin to steps you should follow when carrying out a value stream map analysis.

Value Stream Mapping is a Lean tool that is used to visualize a production process. It helps to increase the value of the product or service by identifying bottlenecks and eliminating waste.

In this value stream mapping tutorial, you will learn

- The Origin of Value Stream Mapping

- What is Value Stream Mapping

- Types of Value Stream Maps

- Segments of a Value Stream Map

- Benefits of Value Stream Mapping

- Value Stream Mapping Symbols

- Creating the Value Stream Map and Analysis

- Value Stream Mapping Tips and Best Practices

- Value Stream Mapping Mistakes to Avoid

- Value Stream Map Templates

The Origin of Value Stream Mapping

The origin of value stream mapping (then known as the “material and information flows”) can be traced back to a technique of visual mapping the Toyota Motor Corporation used to understand the material and information flow within the organization.

The term ‘value stream’ was first coined by James Womack, Daniel Jones and Daniel Roos in their book, The Machine that Changed the World in 1990. It was further popularized in Lean Thinking by James Womack and Daniel Jones in 1996.

According to them, a value stream is the “set of specific actions required to bring a specific product through the three critical management tasks of any business…the problem-solving task,…information management task,…physical information task”.

In Learning to See (1998) Mike Rother and John Shook explained in detail the application of the method in manufacturing. Then in 2004, Beau Keyte and Drew Locher discussed the extended application of value stream mapping in office and administrative processes.

What is Value Stream Mapping?

A value stream map, in the simplest of terms, is a way to visualize the steps required to transform a customer request into a good or service, or in other words, a product’s production path from supplier to the customer. It is a lean manufacturing technique used to analyze, understand and optimize the flow of material, information and activities required to produce a product or deliver a service.

A value stream map, which offers a holistic view of the process or the system, can be drawn at any scale; to map a simple administrative process as well as a complicated global-level manufacturing and sales process. This includes, but not limited to, steps such as product design, order processing, production, transportation and customer delivery. IThe mapt helps identify non-value adding steps that should be eliminated and areas in the process that should be improved to achieve better and faster outcomes at a lower cost in a safer work environment.

Types of Value Stream Maps

There are generally two main types of value stream maps, commonly used in process improvement processes. They are the current state value stream map and the future state value stream map. These two are typically used together in a continuous improvement approach where the current state map is initially created to understand the existing process while the future state is developed at a roadmap to implement improvements and achieve the desired state.

- Current State Value Stream Map (Current State VSM): The current state VSM shows the current state or the ‘as-is’ state of the value stream process. It visualizes the existing processes including all steps, activities and information flow, inventory levels, lead times and other useful data. The current state VSM serves as the baseline for comparison with the future state map and helps to identify waste, bottlenecks and areas for improvements.

- Future State Value Stream Map (Future State VSM): The future VSM shows the desired or ‘to-be’ state after implementing the improvements. This includes the optimized process flow, reduced waste, improved cycle times, and other crucial improvements identified. The future state VSM visualizes the target state and helps to convey the vision of the desired process improvements.

Segments of a Value Stream Map

A value stream map can be divided into 3 segments.

-

Production or process flow: In this section, as in a traditional process flowchart, the flow of the process is drawn from left to right. If there are subtasks or parallel tasks, they should also be drawn from left to right beneath the main flow. Drawn this way, it is easier to tell apart the major tasks that occur time and time again throughout the process, from the minor steps.

-

Information or communication flow: In this section (at the top portion of the map) all the communication, both formal and informal, that occurs within the value stream is shown. There’s no standardized flow of communication as communication can flow in any direction.

-

Timelines and travel distances: Timelines appear at the bottom of the value stream map. This set of lines conveys the time-related data measured in the process improvement. While the top line indicates the process lead time, the bottom line indicates the total cycle time (some maps contain labor content instead of cycle time; when that’s the case, the line is called total work content). The other line, placed at the bottom of the map shows the travel distance (of the product or work or of the people moving) through the process.

Benefits of Value Stream Mapping

Value stream mapping could benefit companies of all extents as an effective tool to evaluate existing business or work processes. Some key benefits are summarized below.

Helps to visualize the entire value stream: Provide a holistic view of the whole process by helping to visualize the entire value stream required to deliver a product to customers and stakeholders. This helps to understand of how value is created while providing a glimpse of the customer’s perspective. It is also considered useful as a language to observe and examine the value stream.

Helps to identify and eliminate waste: VSM helps to identify and eliminate waste, including inefficiencies in the process such as excess inventory, over-processing, delays, transportation waste, and defects. By visualizing and analyzing the process in detail, organizations can identify the sources of waste and take targeted actions to eliminate them, resulting in improved efficiency, reduced costs, and enhanced quality.

Helps to improve the process flow: Value stream mapping helps to identify issues in the process flow and optimize the flow of materials, information, and activities. By mapping out the current state and then the future state, organizations can pinpoint the opportunities to streamline activities, reduce cycle times, minimize handoffs, and improve the overall process flow leading to reduced lead times and improved customer satisfaction.

Facilitates cross-functional collaboration: VSM is a collaborative effort involving various departments and other relevant stakeholders. All parties will be able to gain a shared understanding of the process and collectively identify opportunities for improvement. It also helps to deepen employees’ understanding of the work system and promotes cross-functional collaboration and effective communication.

Provides a roadmap for improvement: VSM is a powerful tool that can help to improve manufacturing production workflows. It can serve as a roadmap for process improvement via the future state map that will help to prioritize improvement initiatives, set targets and track progress over time. VSM also provides the basis for measuring the impact of improvement efforts and supports sustainability initiatives by providing a clear vision of the desired state.

Value Stream Mapping Symbols

There are standard symbols used in drawing value stream maps. These can be typically used to map manufacturing processes. However, in VSM you can devise your own symbols to represent different components in the process for easy understanding. As long as the team involved in the mapping process is familiar with the symbols used, you can design your own symbols to match the needs of your own organization.

Following are the most commonly used VSM symbols.

Value Stream Mapping Process Symbols

| Symbol | Name | Description |

|---|---|---|

| Customer/Supplier Icon | When placed in the upper left corner it represents the supplier, and when placed in the upper right corner, it symbolizes the customer | |

| Dedicated process flow icon | Symbolizes the continuous material flow through a department, process, operation or a machine | |

| Shared process icon | Represents a process, operation, work center or a department that is shared by other value stream families | |

| Data box icon | Placed under icons that carry significant data (such as quantity produced per day, the quantity of waste, cycle time etc.)needed to analyze and observe the system | |

| Workcell icon | Used to indicate multiple processes that are integrated into a manufacturing workcell |

Value Stream Mapping Material Symbols

| Symbol | Name | Description |

|---|---|---|

|

Inventory icons | Represents inventory between two processes |

| Shipments icon | Symbolizes the movement of raw materials from the supplier to the factory, and of finished goods from the factory to the customer | |

| Push arrow icon | Can be used to indicate the ‘pushing’ of material from one process to another | |

| Supermarket icon | Also known as a Kanban stockpoint, is a symbol for a supermarket | |

| Material pull icon | This icon is used when supermarkets connect to downstream processes | |

| FIFO lane icon | Represents a First-In-First-Out inventory system that limits input. ‘MAX’ indicates the maximum number of items that can be allowed to pass through the FIFO lane | |

| Safety stock icon | Represents a safety stock that can be used to protect the system when disruptions such as downtime, system failures etc. occur | |

| External shipment icon | Symbolizes shipment of raw materials to/ from the supplier or of finished goods to the customer |

Value Stream Mapping Information Symbols

| Symbol | Name | Description |

|---|---|---|

| Production control icon | Symbolizes a central production scheduling or control department | |

| Manual info icon | Represents the general information flow from memos, reports etc. | |

| Electronic info icon | Maps the flow of electronic information such as the internet, LANs, WANs etc. | |

| Production Kanban icon | Is used to indicate the quantity to be produced as pulled by the customer | |

| Withdrawal Kanban icon | Symbolizes instructions about transferring parts from a supermarket to the receiving process | |

| Signal Kanban icon | Used to indicate the number of items in a batch that needs to be produced to restock them in the supermarket | |

| Kanban post icon | Represents the location where Kanban signals reside for pickup | |

| Sequenced pull icon icon | Represents a pull system that offers instructions to subassembly processes to manufacture a product without using a supermarket | |

| Load leveling icon | A tool that can be used to batch Kanbans to level the production volume | |

| MRP/ ERP icon | Indicates scheduling using material resource planning and enterprise resource planning | |

| Go see icon | Refers to using visual means to gather information | |

| Verbal information icon | Indicates the flow of verbal and personal information |

Value Stream Mapping General Symbols

| Symbol | Name | Description |

|---|---|---|

| Kaizen burst icon | Is used to highlight the improvements that should be done at specific processes to achieve the future state map | |

| Operator icon | Represents the requirement of an operator’s presence in a certain location | |

| Other information icon | Icon to indicate other information that is useful or could be potentially useful |

Creating the Value Stream Map and Analysis

A value stream map outlines the sequence from the input of raw materials to the delivery of the finished goods or services to the customer. This mapping event can be divided into 4 stages that are described in detail below.

Step 1: Preparation

The preparation step is crucial to the successful implementation of the ideal state map. This step involves getting together a competent team to carry out the mapping process. While the team should include cross-functional participants, having a value stream manager to lead the team and set guidelines would make things easier.

During the preparation period, the team and the manager should measure the scope of the mapping event, decide the business objectives and ready plans for difficulties the team might come across.

It is equally important to identify the product family that will be mapped. A product family includes a group of products of services that share the same process steps. Drawing all of your product flows in one single map would make things complicated; therefore always outline one product family in one map.

Tip: Use a product or service matrix to identify the families of products or services

Step 2: Creating the Current State Map

The current state map serves as a starting point to the process improvement. The current state map visualizes the process at its existing state. It helps discover the ineffective and wasteful practices in the current system and find ways to eliminate them.

Drawing a current state map requires gathering information on the product’s production path. To do this, you need to walk down the path the product takes as it travels through the production factory.

First, draw a rough sketch of the entire value stream (of information and material flow) to help everyone involved understand the skeleton of the map.

Start from the most downstream processes (from the customer end) and move upstream as you draw the current state map. Collect the following data as you go on,

-

Total time per workday

-

Regularly planned downtime such as lunch breaks or meetings

-

Number of people working in the process

-

Quantity of work a person performs within a day

-

Number of product variations

-

Pack size

-

Cycle time (from the beginning of the process to its completion)

-

Queue time (how long a work unit waits until a downstream process is ready to work on it)

Once the process data has been collected you can proceed to draw the current state map following the below steps.

- Begin by drawing the external (or internal) customer and supplier at the top of the page. If the customer and the supplier are separate, draw the supplier icon on the upper left-hand corner, and customer on the upper right-hand corner. Then list down their requirements.

- Draw the entry and exit processes to the value stream (far right and far left portions of the page).

- Create a map shell by drawing the processes (beginning from the furthest downstream point) between the entry and the exit processes.

- List all the attributes of the processes.

- Add queue times between each process. Use the same unit of measurement for all queue times (hours or days).

- Proceed to map all the communication flows that occur within the value stream.

- To identify the type of workflow, add push or pull icons.

- Add any other data left to complete the map

While this sequence of steps is a generic one, you can always modify it to match the needs of your own organization’s value stream. (Refer to Template 2 for an example of a current state map)

Step 3: Create the Future State Map

Once the current state map is documented and lean metrics (which are needed to help you achieve the lean goals you have set) have been decided, the next step is to draw the future state map. While drawing the current state map you will be able to identify the areas of overproduction and of waste in the current production system. This information you gather becomes the basis of your future state map.

Step 4: Planning and Implementation

The final step is creating an action plan to implement the ideal production path you have designed with the future state map. The best way to do this is by breaking down the future state map into smaller segments and proceed to implement changes within one segment at a time.

The work plan should have measurable goals as well as checkpoints. When the future state map is implemented, you will be able to create a new and improved current state map, and to keep generating better results the cycle should continue.

Tip: Hold an annual value stream review to monitor improvements

Value Stream Mapping Tips and Best Practices

To create an effective value stream map, make sure to carry out a careful analysis and planning. Here are some tips and best practices for creating a VSM.

- Clearly define the boundaries and the scope to ensure the VSM is focused and relevant. Identify the starting and ending points, key processes, activities, and information flows, that are within the scope essential to improvement planning.

- Involve cross-functional teams. Value streams include multiple functions or departments within an organization, and as such, it is essential to involve representatives from all these relevant functions and departments when creating the VSM. This will ensure that different perspectives and expertise are considered.

- Use standardized symbols. Make sure to use the standard VSM symbols to create a clear and consistent visualization of the process. This will make it easier for team members and stakeholders to understand and interpret the VSM.

- Make sure the data that you gather is accurate. Collect data on cycle times, lead times, inventory levels, and other related metrics to provide a realistic representation.

- Collaborate with all relevant stakeholders, including team members, process owners, operators, etc. Invite them to discussions, obtain their input, and include their feedback to ensure that the VSM is accurate and has the buy-in of all involved.

- When creating the VSM, keep the focus on the value. Identify and map the value-added activities that directly contribute to the customer requirements. Differentiate such activities from the non-value added ones and waste. This will help to identify opportunities to reduce waste and improve processes.

- Don’t forget to validate the VSM with the actual process and data. Go through the process, observe, and measure the actual activities and inventory levels to ensure an accurate VSM. This will help to avoid discrepancies.

- Continuously update and improve the VSM as process changes and improvements are implemented. Regularly review and update to reflect the current state and the progress toward the future state.

Value Stream Mapping Mistakes to Avoid

-

Splitting up the mapping task among different departments in the hopes of stitching the individual segments together later at the end. This makes things complicated. When carrying out a value stream analysis, it is essential to have a cross-functional team which works together during the mapping event. Make sure that everyone involved in the mapping event is well educated in VSM. And there should be a head figure (value stream map manager) who can lead the team throughout the process.

-

Rushing through the current state mapping step. If the team does not spend enough time to collect accurate data on the current state and analyze them thoroughly during this period, implementation of the future state map will not be successful.

-

Drawing the value stream maps without metrics. As mentioned earlier, a VSM has three parts; workflow, information flow and the timeline. Without the timeline, it is not possible to measure the time it takes people in the process to perform tasks or to gain insight into errors that may lead to organizational chaos. Without metrics, it is also difficult to measure how much progress you have made.

-

Not involving the right people. As mentioned, the VSM process requires input and collaboration from all relevant stakeholders. Therefore, ensuring that the right people from all relevant functions or departments are involved in the process is important.

-

Overcomplicating the value stream map. The purpose of the VSM is to provide a clear visualization of the process. As such, make sure not to overcomplicate the map by using too many symbols, unnecessary details, or cluttering the layout.

Value Stream Map Templates

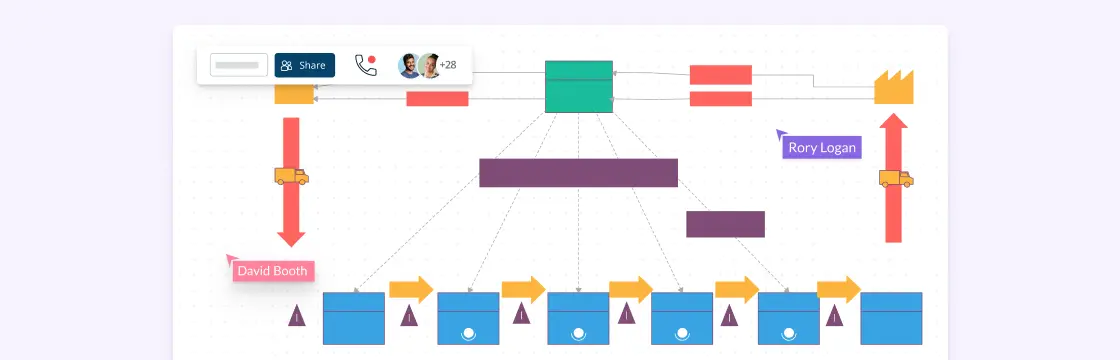

Template 1 - Funnel Shape Value Stream Map

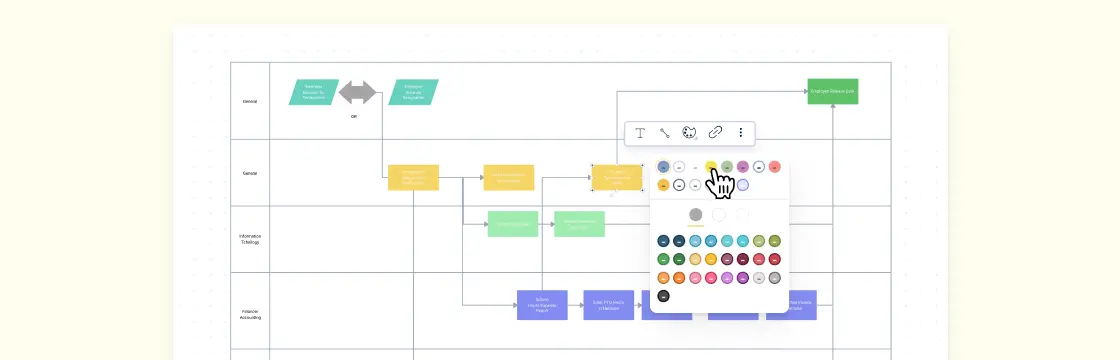

Template 2 – Toyota Production System Value Stream Map (Current State)

Template 3 – Supply Chain Management Value Stream Map

Template 4 – Future State of the Green Value Stream Map

Template 5 – Pyramid Shape Current Value Stream Map

Template 6 – Pipe Shaped Value Stream Map

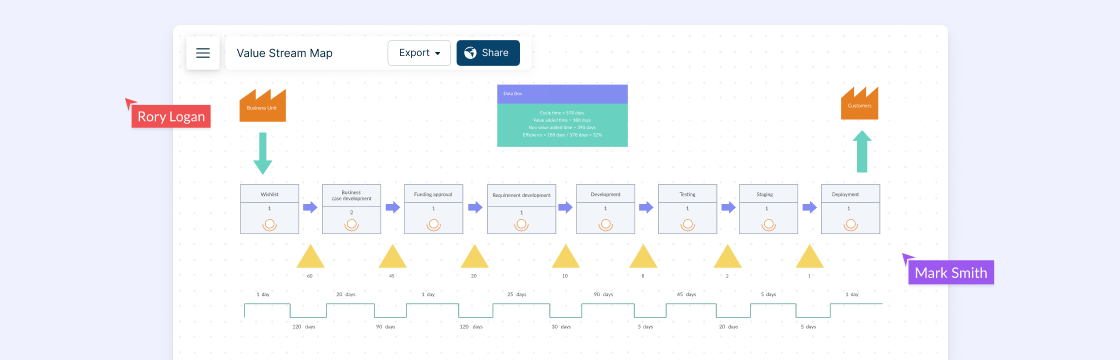

Template 7 – VSM for Software Development

Template 8 – Value Stream Map Template

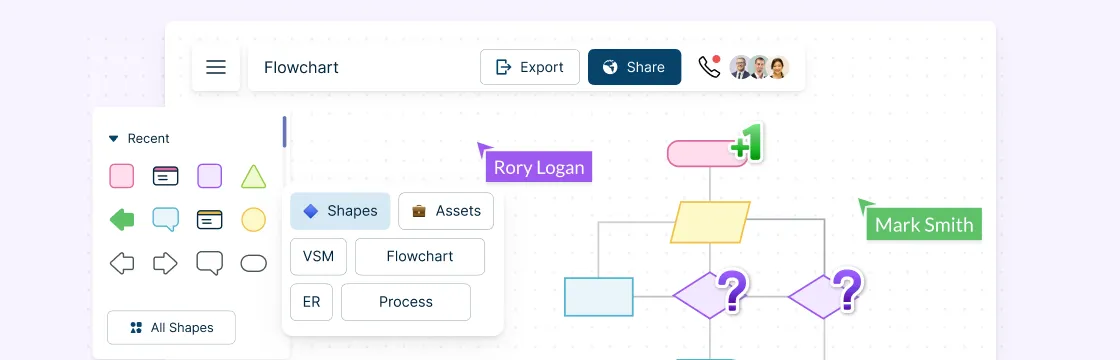

For more professionally designed VSM templates, visit the Creately Diagramming Community.

Feedback on the Value Stream Mapping Tutorial

This value stream mapping guide covers everything important you need to know about value stream maps. If you have any questions regarding the guide, leave a comment below.

More Diagram Tutorials

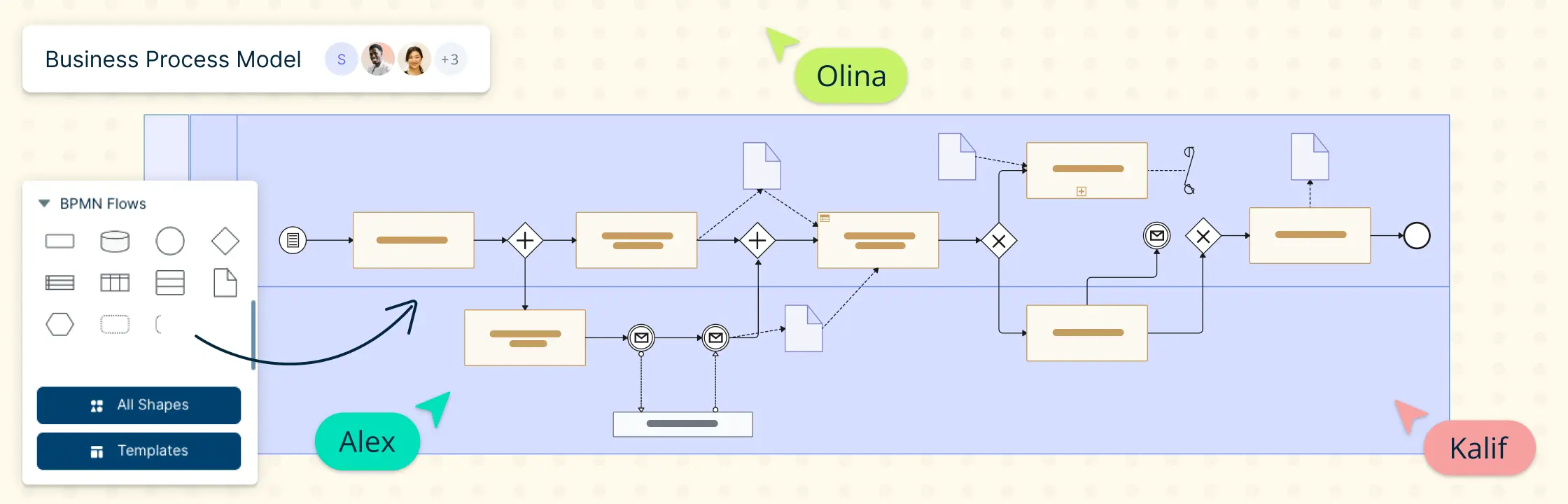

- Business Process Modeling Tutorial (BPM Guide Explaining Features)

- Ultimate Flowchart Guide (Complete Flowchart Tutorial with Examples)

- Use Case Diagram Tutorial (Guide with Examples)

- Sequence Diagram Tutorial: Complete Guide with Examples

FAQs About the Value Stream Map

Once you have identified the required improvements from the value stream map, you can develop an action plan to address the areas. Here are some tips to follow:

- The action plan should include specific tasks, timelines and responsible parties.

- Prioritize the tasks based on their potential impact and feasibility.

- Ensure the tasks are SMART.

- Assign accountability for each task.

- Regularly review progres.

- Insufficient data collection

- Lack of stakeholder engagement

- Incomplete scope definition

- Inaccurate process mapping

- Not differentiating between value-added and non-value-added activities

- Not considering the entire value stream

- Not validating the accuracy with stakeholders

- It is only applicable to manufacturing

- A one-time activity rather than a continuous process

- Only useful for cost reduction

- Complex and difficult to implement

- Clearly communicate the purpose and benefits of the process

- Involve team members in data collection and analysis

- Encourage them to provide feedback and input

- Empower the team members to identify improvement opportunities

- Provide training and support on value stream mapping principles and tools